Fog computing

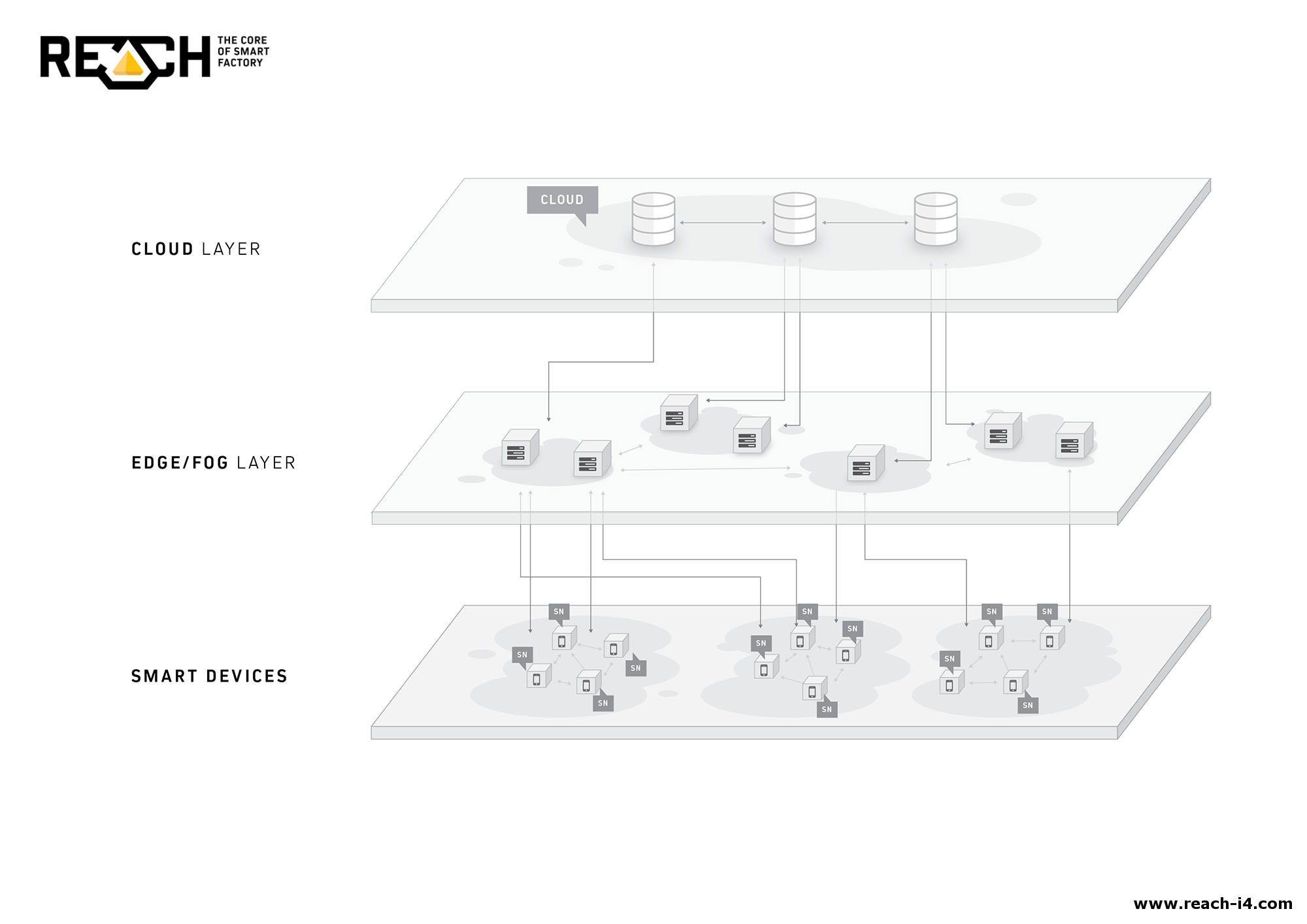

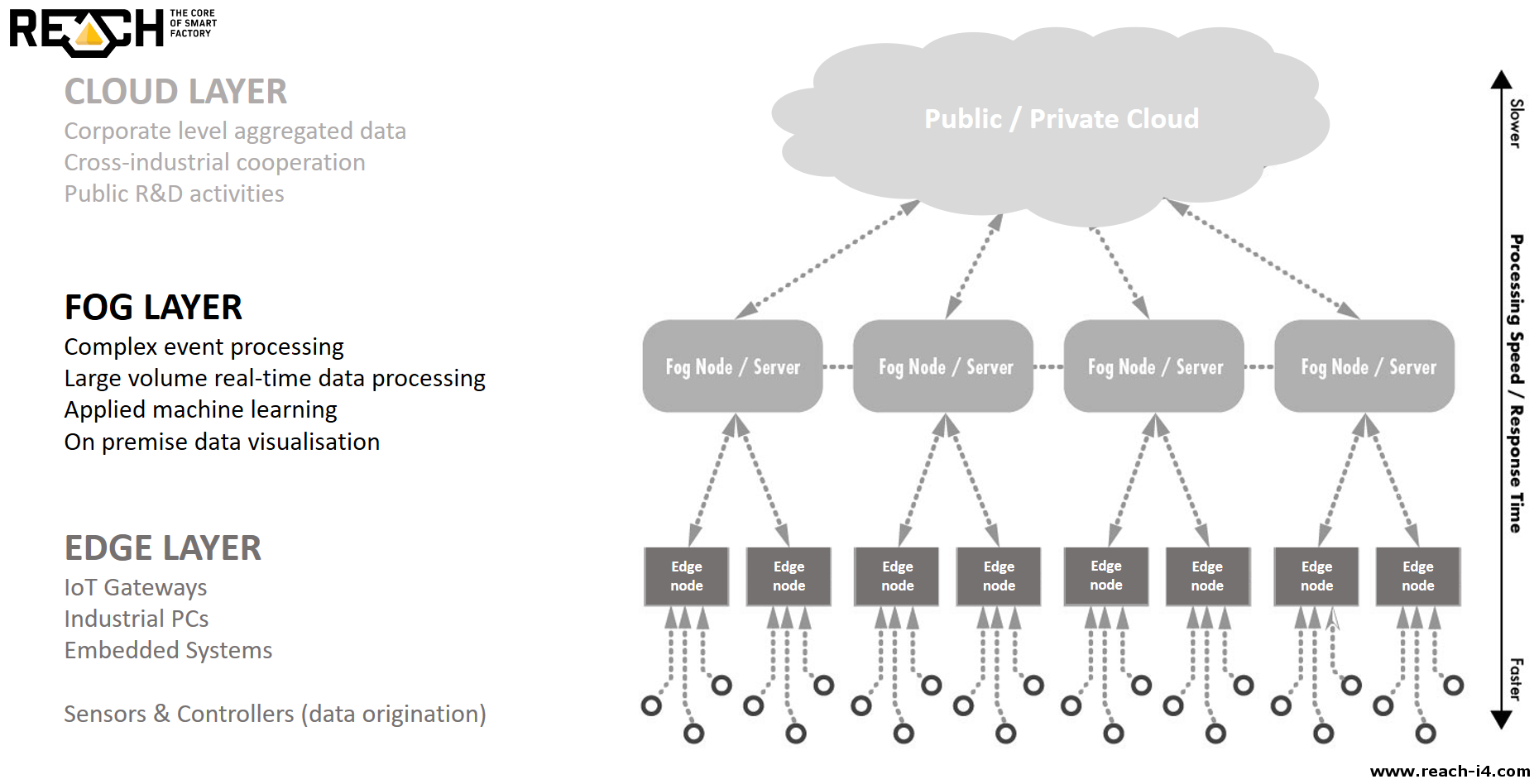

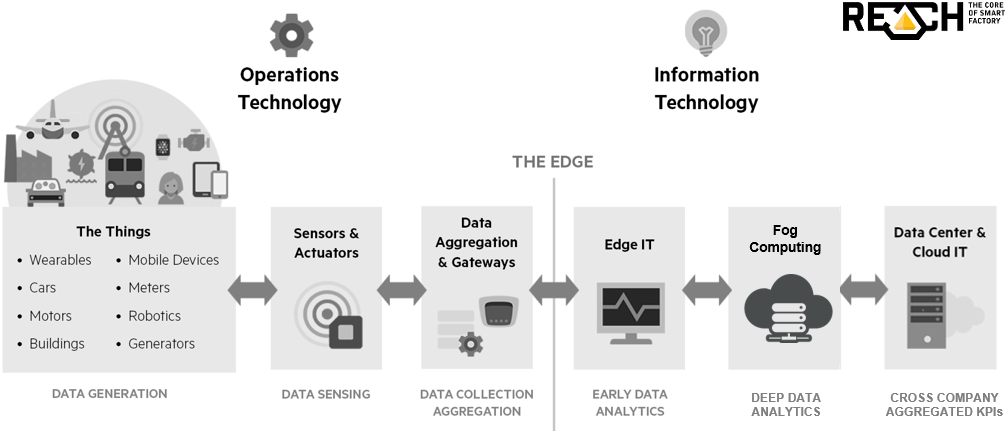

In this context, „Fog” means that „Cloud” moves down, closer to the ground, to the machines, sensors and legacy systems.

Read more

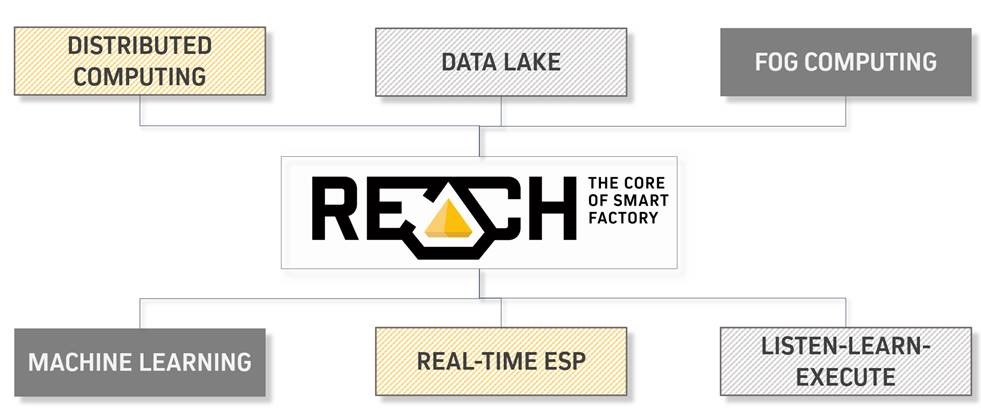

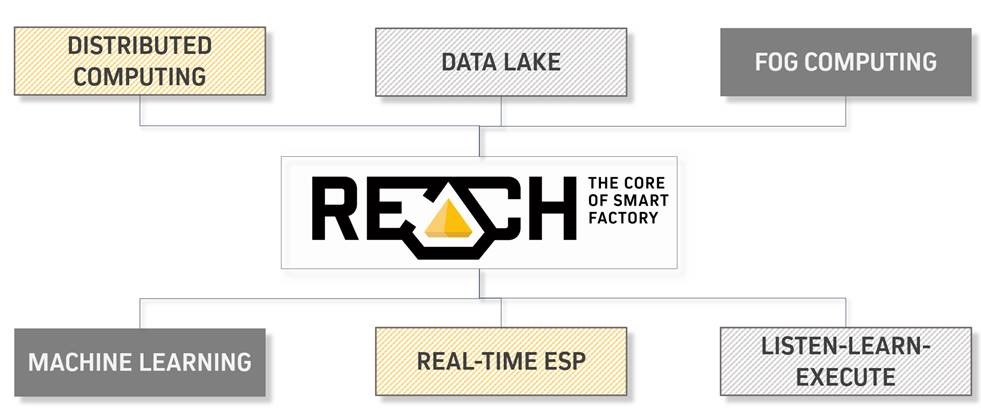

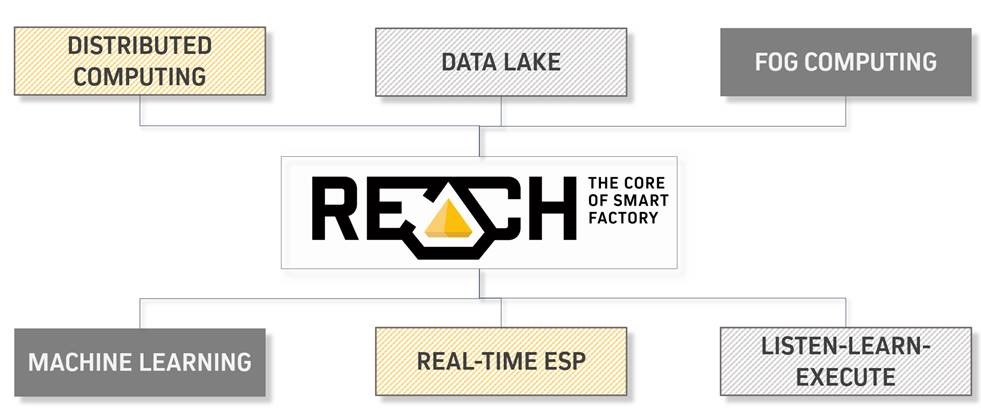

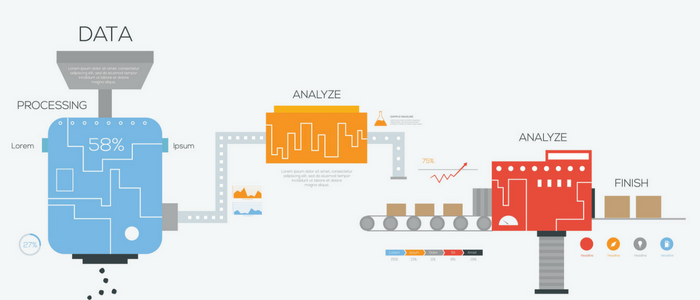

Industry 4.0: The different but particularly collaborative devices’ integrated operation could be realized in a huge system controlled by AI, which can handle simultaneously the past’s heritage, the present’s urgency and the future’s uncertainty for the agile mass customization on the whole value chain. From an IT perspective this needs an IoT platform for the integration and the fast and smart processing. That’s what REACH offers. We combine state-of-the-art Fog computing, Big Data technologies and Machine Learning to help our customers realize the Smart Factory transition and create a digital twin of their production plants.

We proudly announce the category and overall win of the REACH Solutions – MaxWhere joint team on the Industry 4.0 Hackathon, which took place in Linz last November. The Pioneers I-4.0 hackathon is one of the most prestigious among engineering competitions across Europe. The challenge was to create a 3D Digital Twin of a logistics robot and conveyor system, control the model with the provided data and show the log information in real time. We took the TGW Logistics category and the overall win ahead of nearly 20 startups and teams, providing a “spectacular and informative” 3D VR show and a fully functional architecture. With the help of our solution, TGW Logistics is now able to rapidly back-track errors in the automated warehouse systems, letting engineers do troubleshooting even from distant locations.”

Collect and store data from any source, structured or unstructured, in batch or real-time. Built-in pre-defined industry specific data models to use ingested data in dynamic attributes that are scored, calculated and updated in real-time.

Turn data into actionable insights by giving the tools required to monitor production process in real-time, and to intervene when maintenance requirements or efficiency improvement opportunities arise. REACH orchestrates seamless, compelling event-based actions across both physical and digital channels.

M2H and M2M communication and interactions. Right data, right action, right time, right channel, right format. All, but no more. More effective operation, improved HSE (Health, Safety, Environment) with less human resource usage.

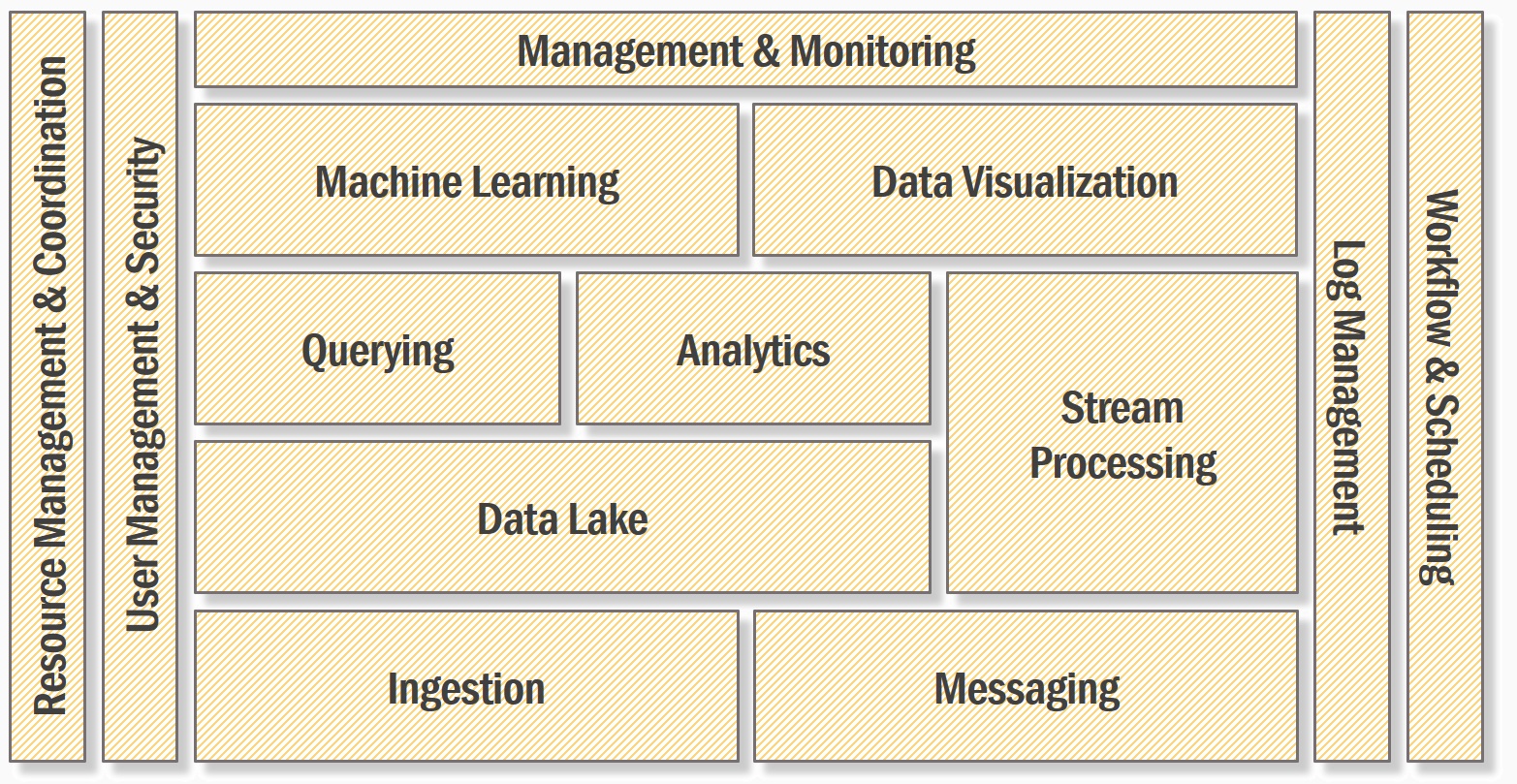

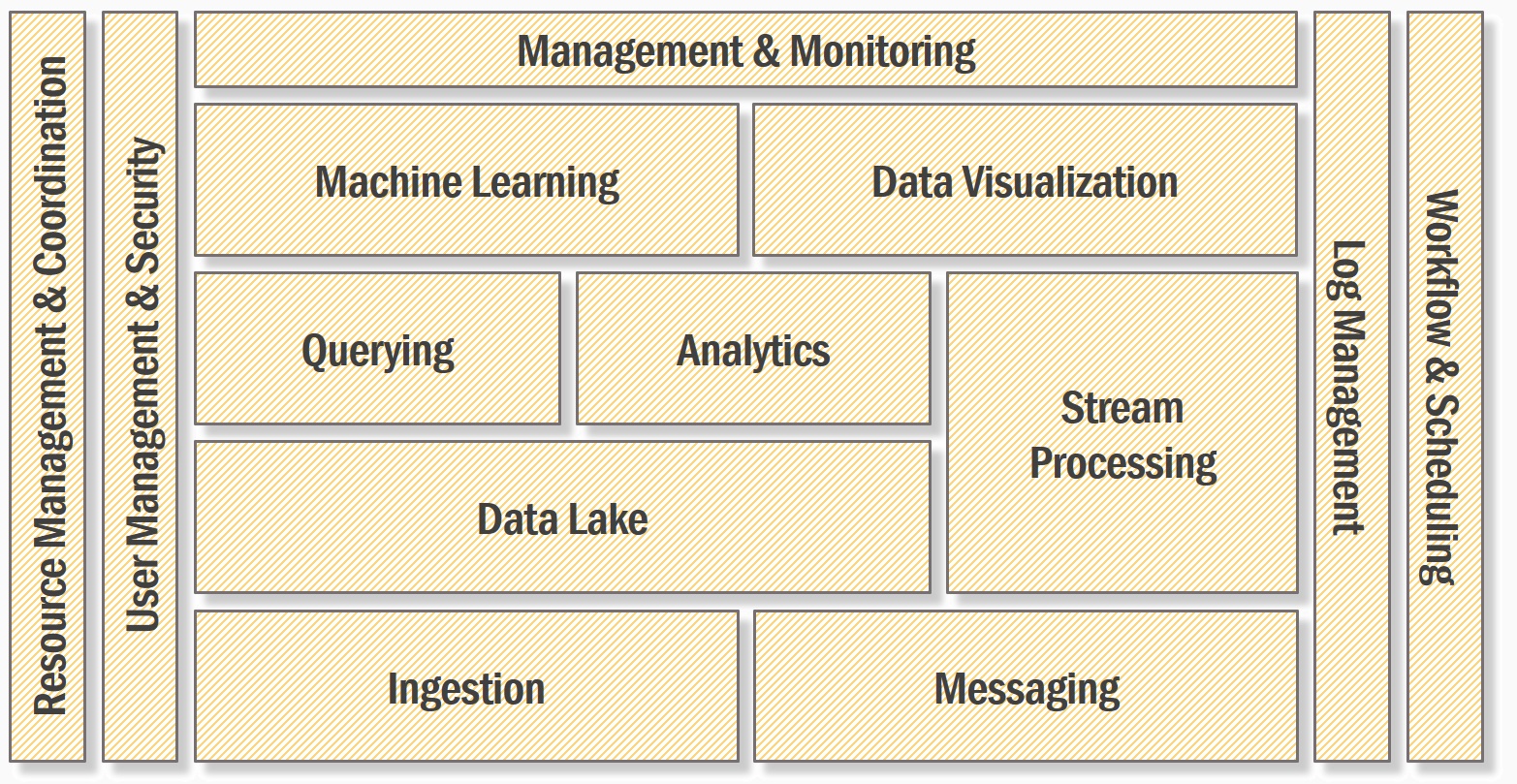

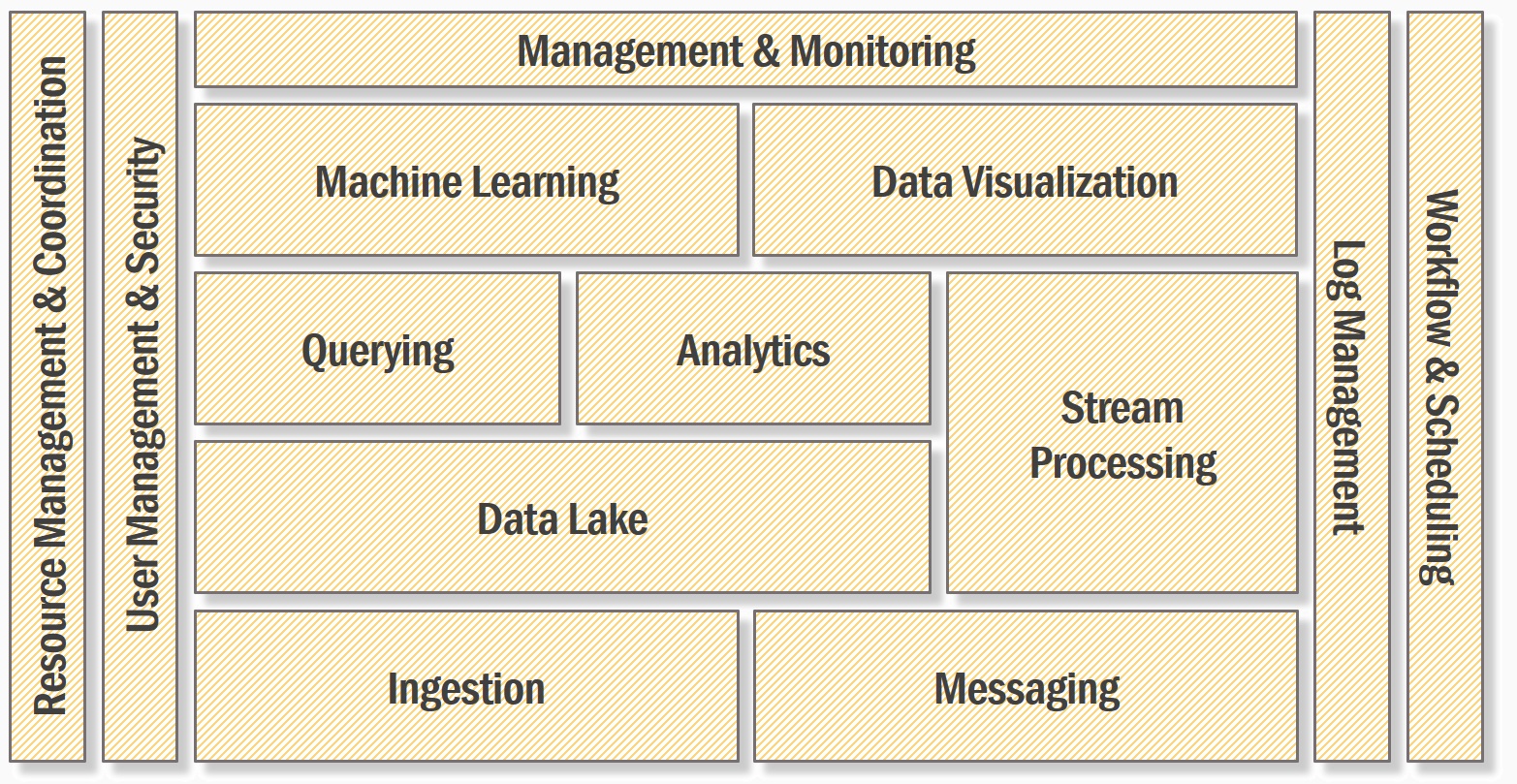

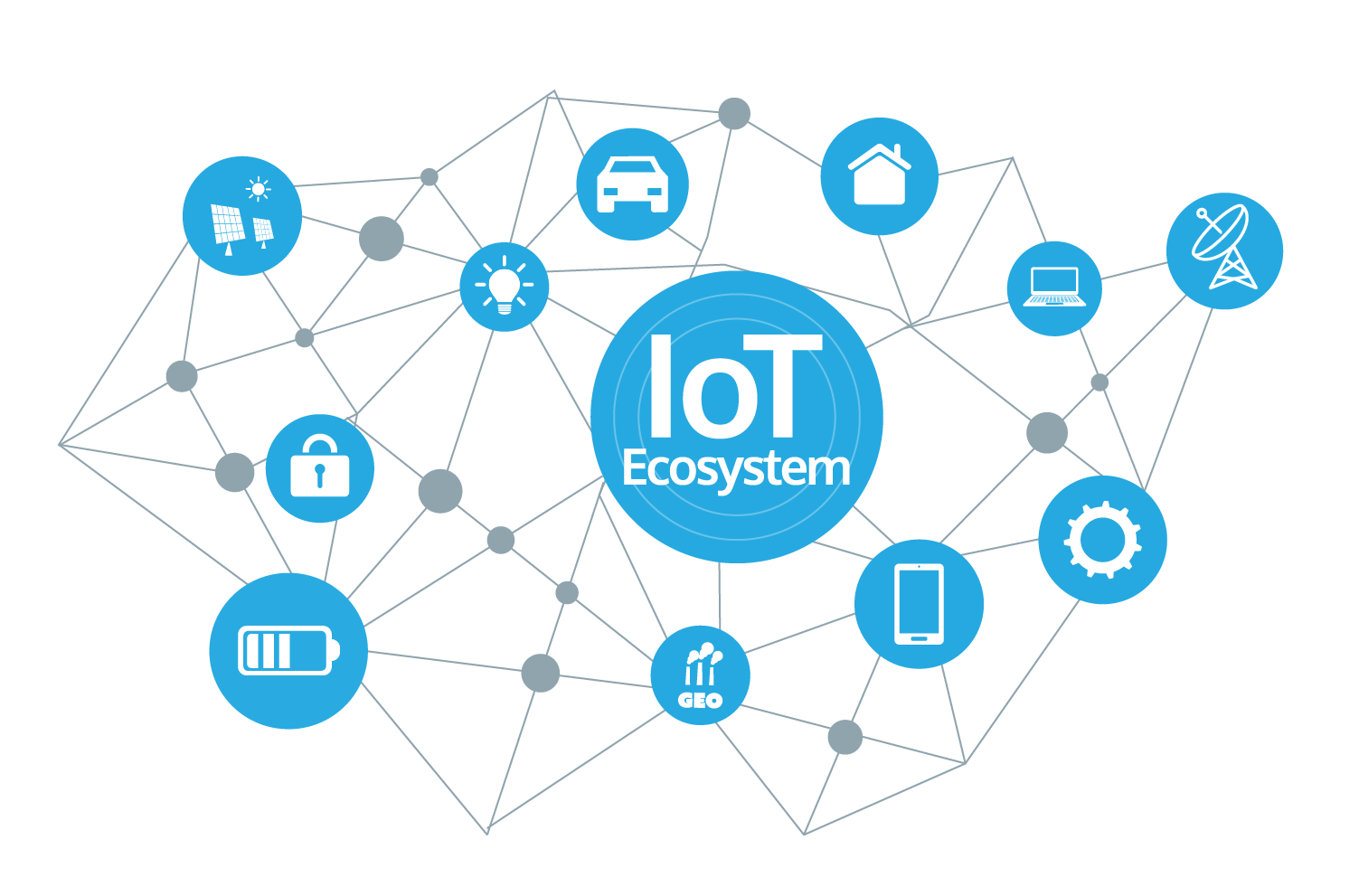

The IoT already exists, but its constituent devices are yet to be united. The IoT Platform is the key for the development of scalable IoT applications and services that connect the real and virtual worlds between objects, systems and people. Our IoT platform (named REACH as abbrevation of Real-time Event-based Analytics and Collaboration Hub) could be the backbone of any IoT deployments as a unifying platform to collect, organize, and activate your data from any source. REACH not only collects and organizes data, but makes it available to other to be used for targeted executing, performance customization, and beyond. Our integrated solution offers:

Connectivity: agents that ensure constant object connectivity and harmonized data formats.

Data management platform to collect, organize, and activate data in reliable, scalable, distributed computing and data storage framework.

Processing and action management: rule engine that allows for real-time actions based on incoming sensor & device data.

Machine learning and analytics: algorithms for advanced calculations and executions, with built-in modules to combine SQL and streaming data processing.

External interfaces: APIs, SDKs and gateways that act as interfaces for 3rd party systems.

REACH ties multiple data sources from across machines, systems, and sensors together into a single platform with ease. With pre-built data connectors, data correlation from multiple streaming data sources happens in real time - log files, sensor data, machine feedback, historical data from databases, social feeds, and more.

The platform leverages historical static data to inform norms and context, while using streaming data to identify anomalies in real time and can automatically alert when any indicator is outside the tolerance.

Takt time is the average time between the start of production of one unit and the start of production of the next unit, when these production starts are set to match the rate of customer demand.

Once up and running, takt time is very easy to measure. Manufacturers operating lean production lines can use this tool to ensure as much "waste" is removed from the process as possible -i.e. minimising the takt time - and monitor performance very closely.

One of the main benefits takt time offers is increased visibility for production line operatives and their supervisors.

OEE breaks the performance of a manufacturing unit into three separate but measurable components: Availability, Performance, and Quality. Each component points to an aspect of the process that can be targeted for improvement. OEE is calculated with the formula (Availability)*(Performance)*(Quality).

Real-time automated data is essential if you want to unlock to the full benefit from OEE. Measure and display OEE so that operators can see it in real time. Measure the OEE for each product being packaged on a particular line, and use the results to compare what lines perform better than others for certain products.

Predictive Maintenance (PdM) techniques are designed to help determine the condition of in-service equipment in order to predict when maintenance should be performed. This approach promises cost savings over routine or time-based preventive maintenance, because tasks are performed only when warranted.

This results in a reduction in unplanned downtime costs because of failure, where for instance costs can reach hundreds of thousands of dollars per day depending on industry.

A general rule of thumb is that costs of poor quality even in a thriving company will be about 10 to 15 percent of operations. REACH® offers opportunity to make significant improvements in this space.

Monitoring the whole manufacturing process – add value to your products

Collecting data from each step and domain of your manufacturing helps identifying the root cause of quality issues. This data – digital content of a product of any kind – also adds value to your products.

Quality early warning systems

Predict early indications of deviations from the standard process and potential excursions.

Real-time tracking of assets (including raw materials, industrial machinery, fleets of trucks, containers, final products, etc.) enables businesses to be well informed about device and equipment status and performance.

This improved intelligence can be used to more effectively prevent quality issues, maintain inventory levels and safety standards, optimize logistics, and detect theft.

However, real-time visibility has been a consistent challenge for asset-intensive companies. It can be solved via sensors and low-cost connected devices that can be embedded into virtually anything, making real-time asset tracking possible.

REACH custom analytics enables you to drill down into fine details and discover correlations you wouldn’t see otherwise. With this feature you can create custom dashboards, visualizations , reports from your factory data, which helps you make better decisions. It also makes easier to discover and understand problems, malfunctions from your processes.

Digital twin is a dynamic digital representation of an industrial asset, that enables companies to better understand and predict the performance of their machines and find new revenue streams, and change the way their business operates. The digital representation provides both the elements and the dynamics of how an Internet of Things device operates and lives throughout its life cycle. A digital twin can be defined, fundamentally, as an evolving digital profile of the historical and current behavior of a physical object or process that helps optimize business performance. The digital twin is based on massive, cumulative, real-time, real-world data measurements across an array of dimensions.

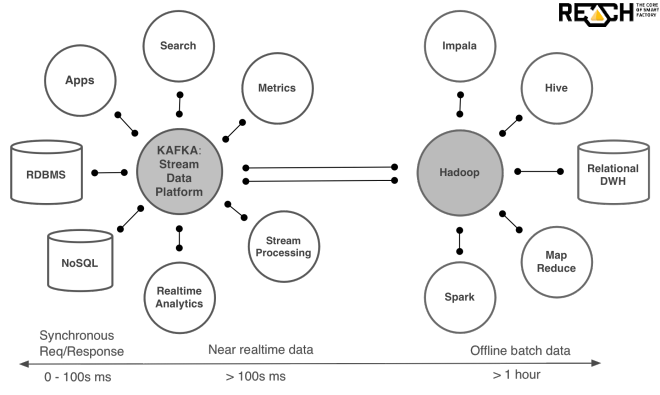

Our technology stack consist of state-of-the-art, future proof technologies, based on three pillars:

The heart of the solution is the most up-to-date computer technology, capable of processing complex events in real time.

The distributed computing framework makes scaling flexible and easy, and adjusts to any performance requirement.

Machine Learning is key to make production more efficient and helps making better manufacturing and business decisions.

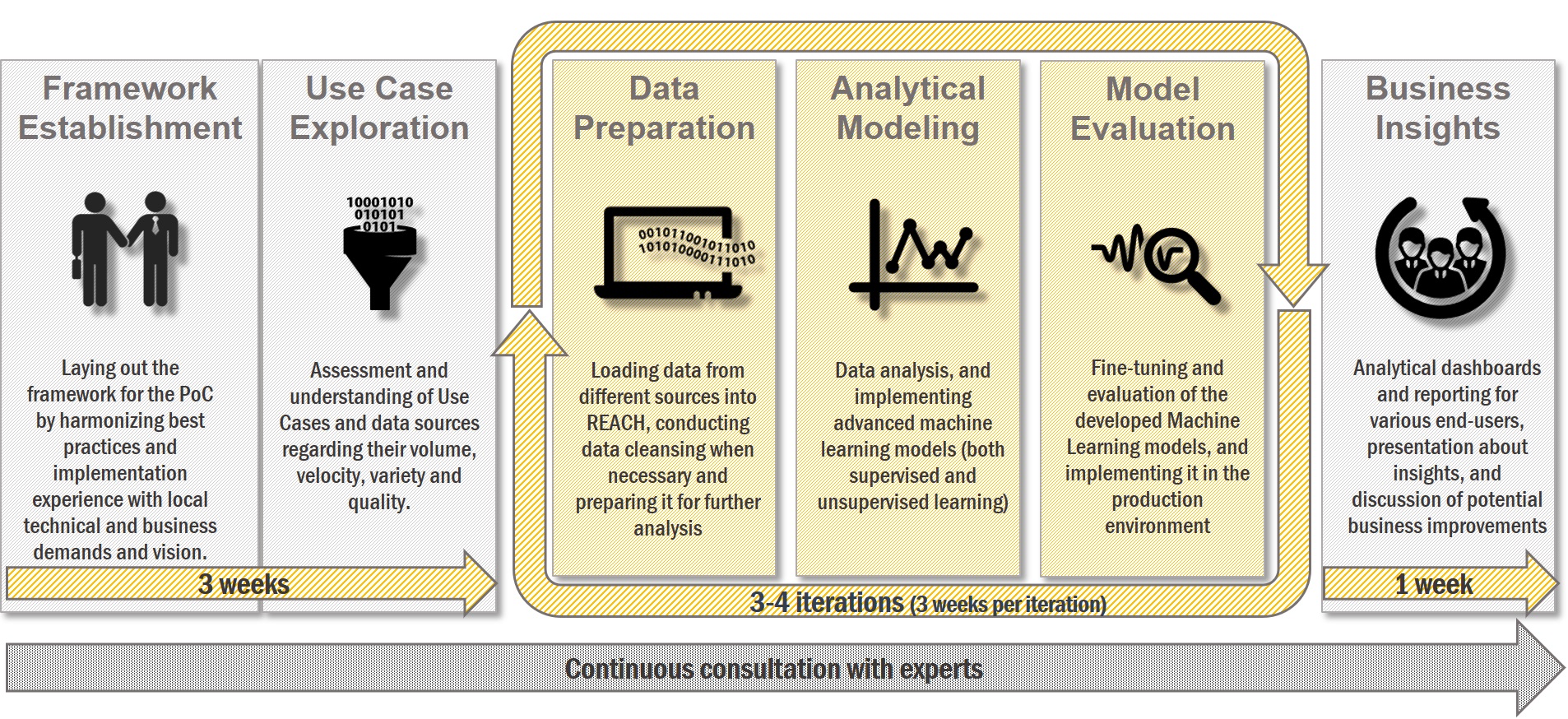

Prove feasibility of a solution with selected components.

Agile approach: pick low hanging fruits (e.g. 3 relevant use-cases).

Short time to value, simplified budgeting (only OPEX).

Non-invasive approach: production remains 100% undisturbed

No hardware investment necessary

Scalable, fast deployable, cost effective

In this context, „Fog” means that „Cloud” moves down, closer to the ground, to the machines, sensors and legacy systems.

Read more

Now it is time to make a comparison between Edge, Fog and Cloud computing.

Read more

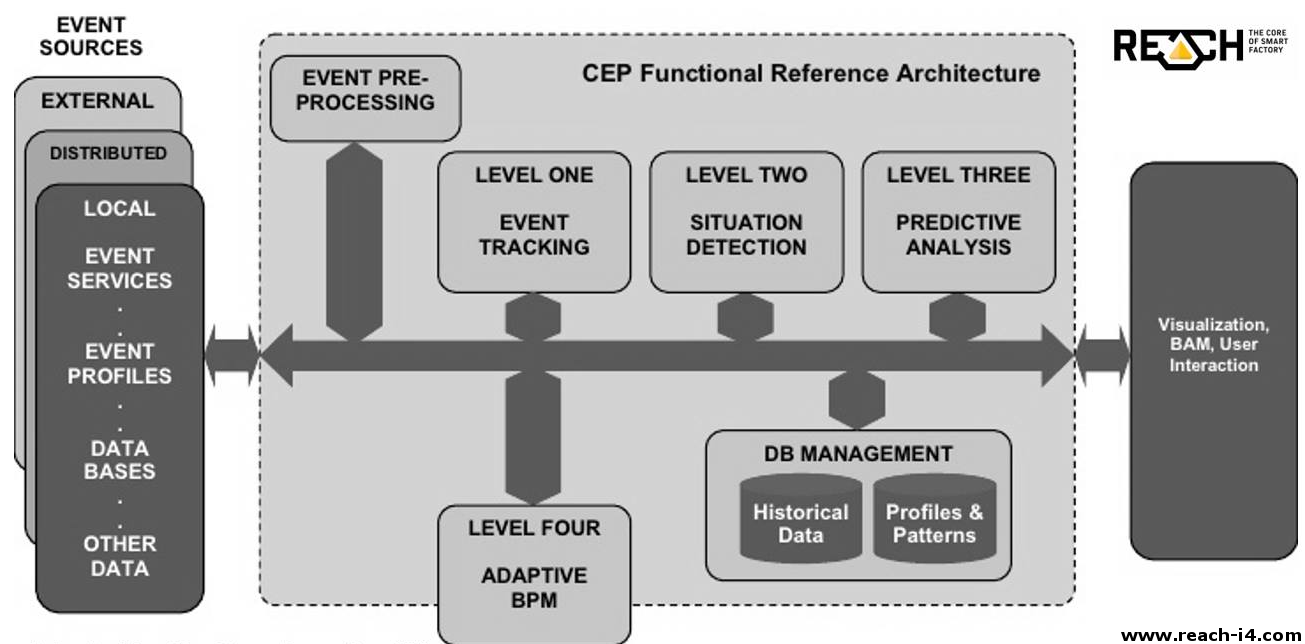

Processing complex events in real time is key to derive business value from your factory data.

Read more

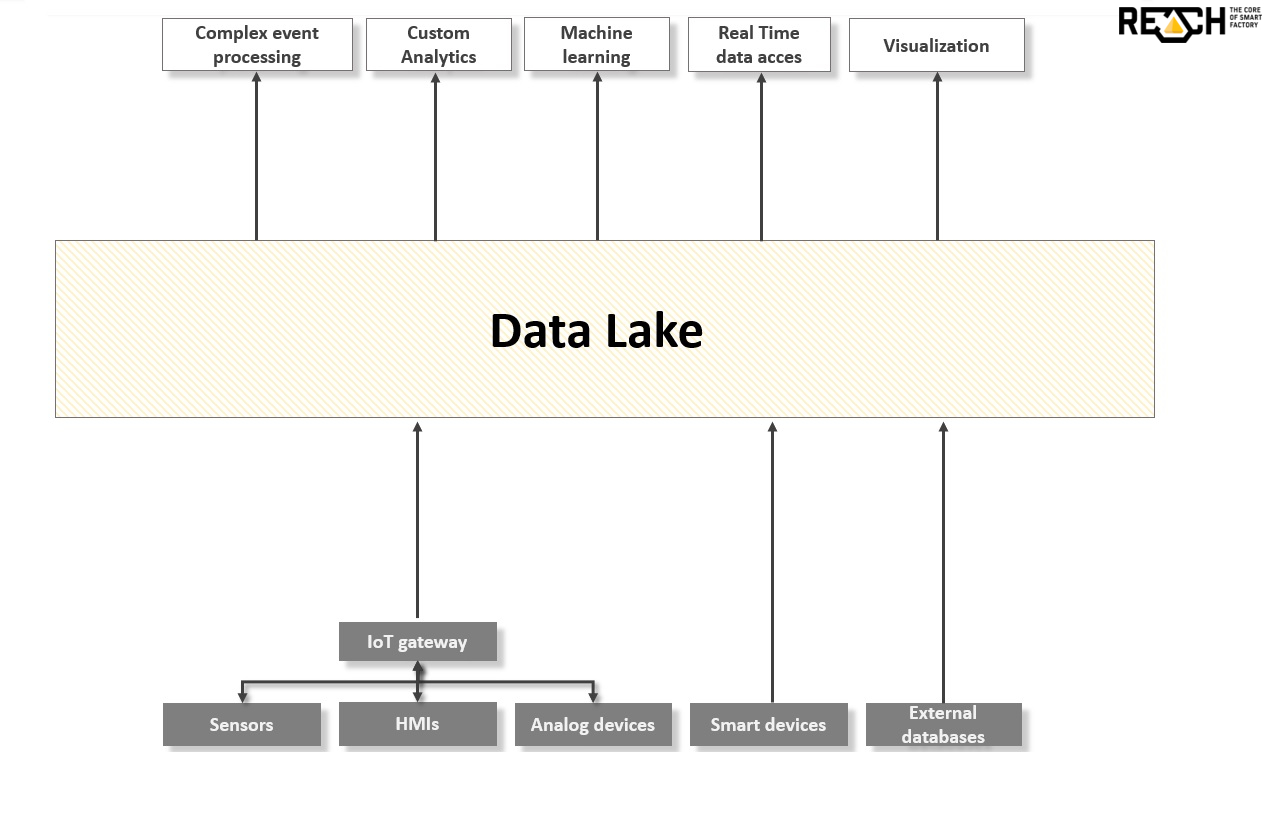

In this post we are going to show why is so important to have a data lake in the era of Industry 4.0

Read more

+36 1 319 55 11

info@reach-i4.com

1138 Budapest, Dunavirág u. 2., I. torony 3. emelet (Gateway Office Park)